Material: Floor grating can be made from materials such as galvanized steel, stainless steel, aluminum, or fiberglass. The material choice depends on the environment where the grating will be used and the specific requirements of the application.

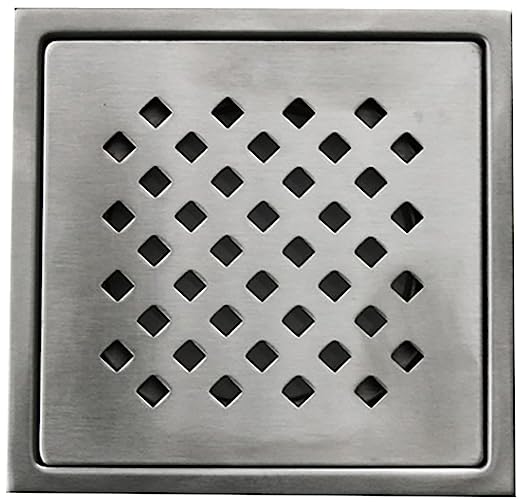

Durability: Grating panels are designed to withstand heavy loads and harsh conditions. They are resistant to wear and tear, corrosion, and weathering.

Load-bearing capacity: Depending on the type and size of the grating, it can support significant weight, making it suitable for walkways, platforms, and catwalks.

Slip resistance: Many floor gratings are designed with textured surfaces or additional coatings to provide slip-resistant walking surfaces, improving safety for workers and visitors.

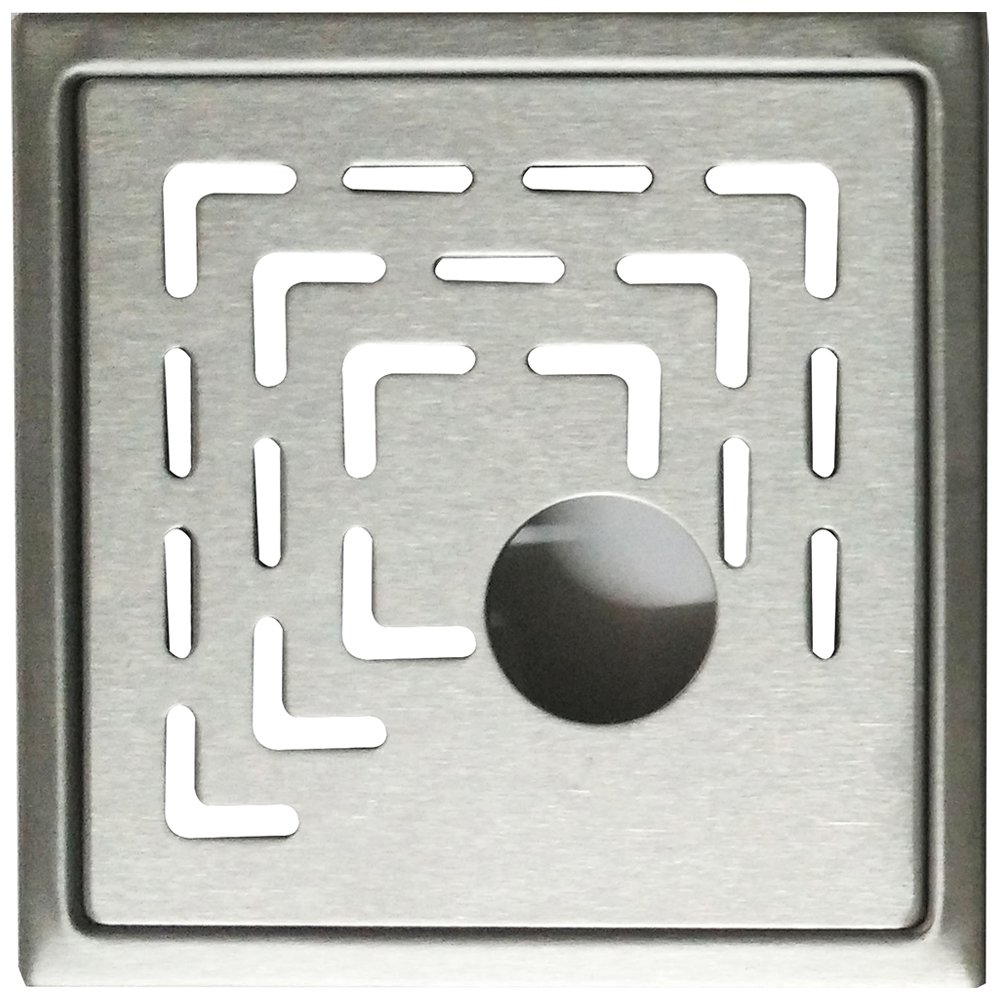

Drainage and ventilation: The open design of floor grating allows for easy drainage of liquids and ventilation, preventing the buildup of water, debris, or other substances.

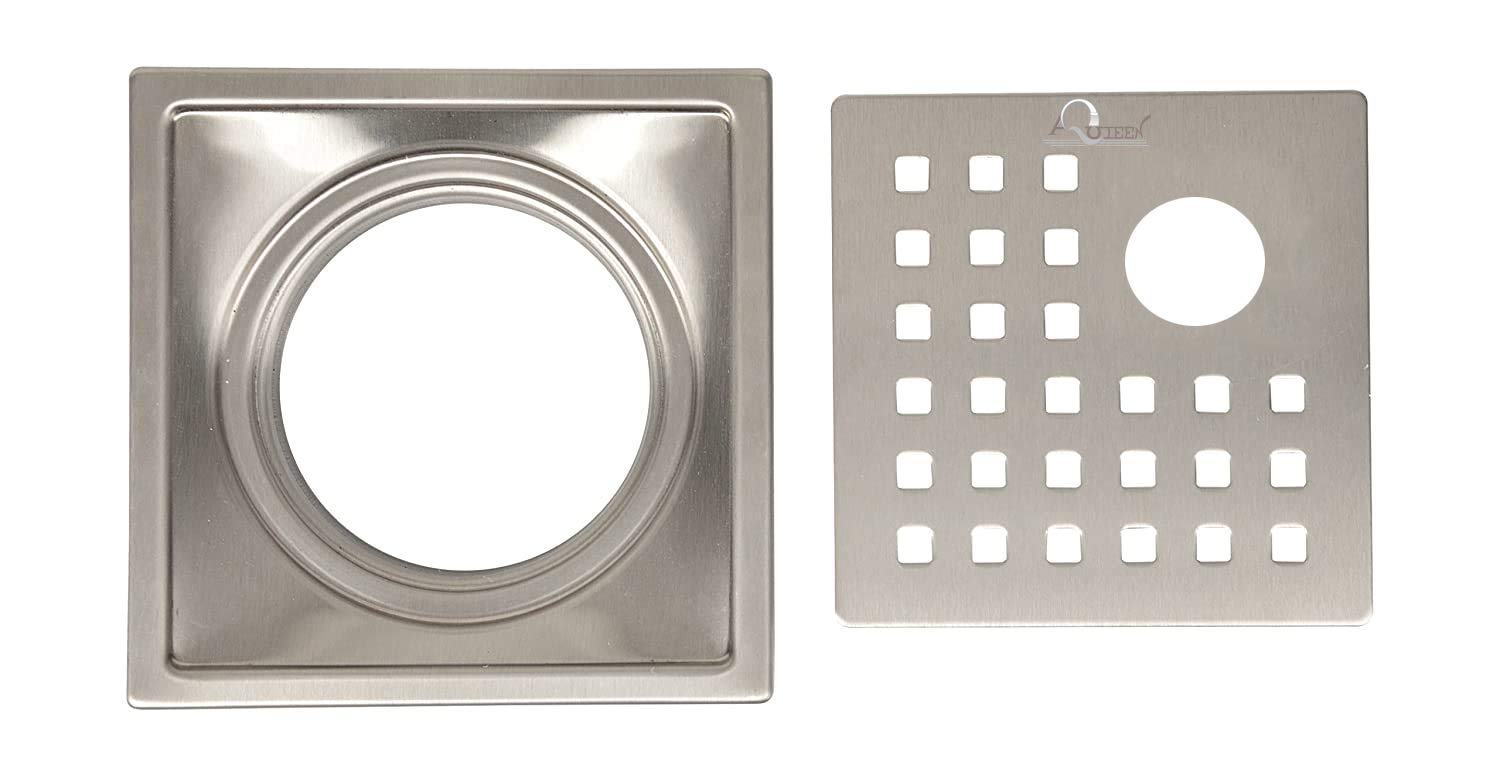

Customization: Floor grating can often be customized to meet specific requirements, including size, shape, and finish.

Ease of installation: Grating panels are usually lightweight and easy to install. They can be fastened or welded in place, depending on the application and material.

Applications: Floor grating is used in a wide range of settings, including industrial facilities (such as factories, refineries, and power plants), commercial buildings (such as shopping centers and offices), transportation infrastructure (such as bridges and platforms), and even in public spaces (such as parks and recreational areas).